Ecommerce fulfillment is the end‑to‑end workflow that starts the moment a shopper clicks “Buy”—syncing inventory, picking & packing items, securing the lowest‑cost carrier, and processing returns—often coordinated by software and warehouse staff. Because fulfillment can absorb 25‑35 % of every order’s cost, nailing these steps is critical for fast delivery, higher customer satisfaction, and repeat sales in today’s hyper‑competitive online retail landscape.

Ever click “Complete Order” and stare at a growing tower of boxes, wondering what to do next? That panic moment is ecommerce fulfillment—the work of tracking inventory, packing boxes, picking the cheapest shipper, and fixing returns. When these steps break, shipping costs soar and shoppers bail.

Don’t stress. This guide shows:

- 🔑 Five must‑do moves that keep your fulfillment process tight and tidy

- 🏠 When to stay in‑house vs. hire help so you keep control and still meet demand

- 💸 Ways to slash costs without slowing delivery or hurting customer happiness

We’ll share real stories, quick checklists, and tools you can use before your next coffee break. Ready to turn that pile of boxes into profit? Let’s dive in.

Jump‑To Guide

What Is Ecommerce Fulfillment?

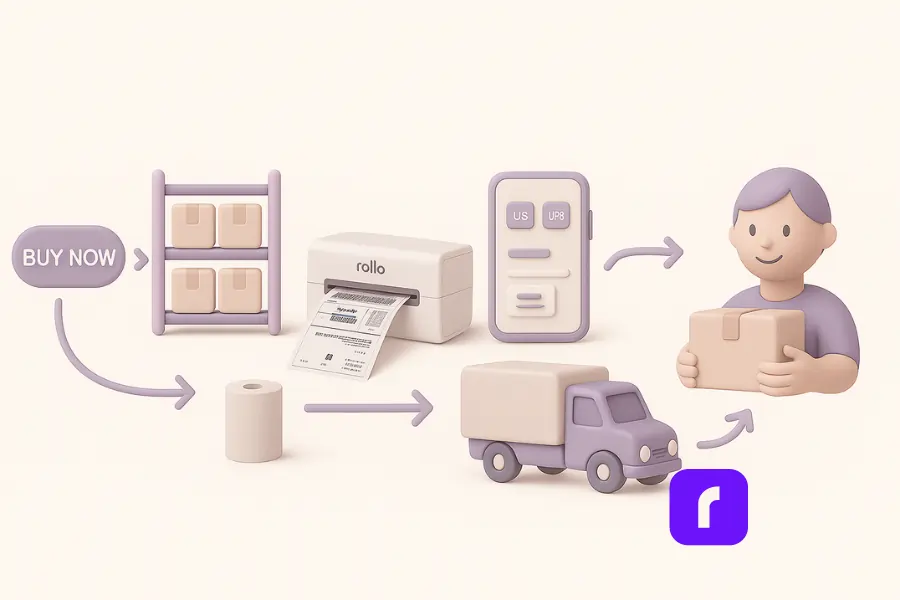

Ecommerce fulfillment refers to all the behind‑the‑screen work of receiving online customer orders, picking and packing items, shipping them at the best rate, and handling returns—while keeping inventory counts in sync across channels. Done right, this order fulfillment process powers smooth fulfillment operations, trims costs, and delights customers who crave quick, trouble‑free delivery.

- 📦 Receive & store stock: track inventory in real time.

- 🏷️ Pick, pack, ship: choose carriers and print labels fast.

- 🔄 Manage returns: restock, refund, and keep shoppers happy.

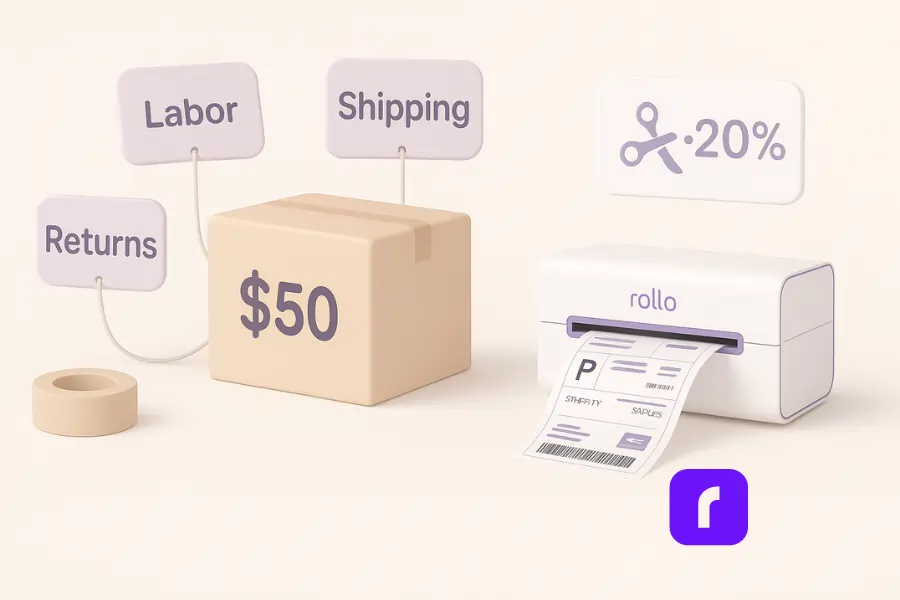

Why Ecommerce Fulfillment Costs More Than You Think

Ecommerce fulfillment stacks up fast. From pick-and-pack labor to rising shipping costs, every step adds a fee—and small business owners often feel it in their margins. Even if you run your own operation without warehouse rent, you’ll still face costs like labor, postage, and return handling.

That’s where smart tools like the Rollo Wireless Label Printer and the free Rollo Ship app make a difference—slashing shipping rates and saving you time on every order. Here’s a look at the typical costs behind a $50 order—and how Rollo helps cut them down.

| Cost Driver | Avg. Cost/Order | % of Order | Cost with Rollo Ship Discounts* |

|---|---|---|---|

| Picking & packing labor | $5.50 | 11 % | $5.50 (fixed) |

| Shipping label + postage | $6.50 | 13 % | $3.25 |

| Returns handling | $2.00 | 4 % | $2.00 (fixed) |

| Total | $14.00 | 28 % | $10.75 |

*Assumes up to 90% off shipping rates via Rollo Ship’s group‑buy discounts.

Escalating Shipping Rates & Fuel Surcharges

- ⛽ Global fuel hikes pushed major shipping carriers to raise base rates 5–7 % this year.

- 📈 Peak‑season fees add up to $1.50 per parcel.

- 📦 Dim‑weight pricing means a fluffy 6‑oz tee can bill as a one‑pound box.

- 💵 Rollo Ship’s 88–90 % discounts on popular services cut the shipping process bill in half.

Warehouse & Labor Pressures

Rents for prime racks are up, and the fight for trained pickers keeps hourly pay climbing. Without a smart warehouse management system, teams spend extra minutes per order hunting SKUs—minutes that turn into dollars. Check our Rollo workflow tweaks to see how targeted automation trims labor without adding headcount.

Which Ecommerce Fulfillment Strategy is Right for You?

Choosing the right fulfillment strategy means finding the sweet spot between control, cost, and customer experience. When you handle fulfillment in-house with Rollo Ship and a Rollo Wireless Label Printer, you keep control of every order while cutting costs and boosting efficiency. Outsourcing to a third-party logistics (3PL) company saves time but often means higher fees, less control, and delayed updates.

| Factor | Rollo-Powered In‑House Fulfillment | Third‑Party 3PL |

|---|---|---|

| Control | Full control over your orders, branding, and customer experience | Limited — you’re relying on 3PL’s processes |

| Up‑front cost | Low hardware cost (Rollo printer) + flexible labor | No equipment needed, but higher per‑order fees |

| Speed to ship | Fast — batch labels, AI order grouping, direct carrier pickups | Fast in big hubs, but you depend on their schedule |

| Visibility | Real‑time dashboard + order sync | Portal updates may lag behind inventory status |

| Savings | Up to 90% off shipping rates + no ink costs + no monthly fees | Discounted rates, but high pick fees, packing markups |

With Rollo Ship and the Rollo Wireless Label Printer, your ecommerce fulfillment strategy stays fully in-house — giving you pro-level speed without third-party markups.

💡 Power Your In‑House Fulfillment with Faster, Smarter Label Printing

Pros of Outsourcing Fulfillment

A skilled third‑party logistics company can ship orders nationwide in a flash. You don’t need to buy shelves, forklifts, or extra insurance. One trusted fulfillment partner also wins bulk shipping discounts. Their crew can jump in during holiday rushes. You get to focus on sales while they move the boxes.

Cons of Outsourcing Fulfillment

Convenience comes with a cost. Every order may carry pick fees and packing mark‑ups. Long contracts can trap a fast‑growing shop. You lose control of how each package looks. Portal updates lag behind real stock counts. Running your own in-house fulfillment with Rollo avoids these pains and still gets carrier discounts.

5‑Step Ecommerce Fulfillment Process

Below is the plain‑English, five‑part path every parcel travels—from the moment your store pings an order to the second a happy customer snaps an unboxing pic. Use it as a checklist or training sheet.

- Order Processing: Your cart pings, an order drops into the queue, and data flows to your WMS. Rollo’s shipping website automates this hand‑off, batching similar orders for one‑click label runs.

- Inventory Storage: Products sit in tidy bins, SKUs facing out, ready for action. Smart slotting and clear aisle labels keep travel time down. Rollo Ship feeds real‑time stock counts back to sales channels to avoid oversells.

- Picking: Workers scan a pick list, grab items, and tick them off. Zone picking, wave picking—choose a method and stick with it. Rollo prints scannable pick tickets that match each batch.

- Packing: Items meet boxes, void fill, and tape. Size‑right packaging trims DIM weight fees. A Rollo wireless printer cranks out 4×6 labels at one per second, no ink, no mess.

- Shipping & Returns: Labels on, boxes out. Customers track progress and, if needed, trigger a painless return. Rollo’s branded tracking page and prepaid return labels protect customer experience.

Master these five steps and you’ll not only tighten up your fulfillment workflow but also make your operation faster, more accurate, and ready to scale when demand spikes. Once those basics are locked in, it’s time to sharpen the details that save you even more time and money.

Receiving & Inventory Sync

Before you can fulfill a single order, your products need a home and a system that keeps stock counts reliable. This first layer of control sets the stage for everything else.

- 🔄 Log inbound cartons, verify counts, and spot damage.

- 🔄 Manage inventory by slotting new SKUs right away.

- 🔄 Lean on shipping software for auto‑reorder points.

- 🔄 Rollo pushes real‑time channel sync, so stock levels stay honest.

A tight inventory sync means fewer stockouts, smoother order flow, and fewer “oops” moments when you realize you’re sold out. With this foundation set, your picking and packing process can really hit its stride.

Picking & Packing Best Practices

Now that inventory is squared away, it’s all about speed, accuracy, and keeping errors out of the box. A few smart tweaks to your picking and packing flow can save hours—and plenty of headaches.

- ✅ Batch similar SKUs to speed walks.

- ✅ Use color‑coded totes for error‑proof flow.

- ✅ Swap bulky printers for efficient ecommerce fulfillment tools.

- ✅ Rollo’s wireless unit prints a crisp label every second, zero ink.

Small upgrades to your picking and packing routine can pay off big over time—cutting wasted motion, reducing mistakes, and freeing you up to handle growing order volumes without extra hands. And once orders are packed tight, delivering a top-notch customer experience comes down to how you ship and track every box.

Shipping & Tracking Transparency

Speed is great; clarity seals the deal. Customers gauge customer satisfaction by how smoothly tracking links work. A branded page boosts customer experience, cuts “Where’s my order?” emails, and nudges repeat buys—exactly what you get when Rollo’s tracking screen pops up on every shipment.

🚀 Handle Ecommerce Fulfillment Like a Pro with Rollo Ship

Growing Beyond the Garage: Next‑Level Fulfillment Tips

As your ecommerce business scales, the entire fulfillment process gets more complex. Use these simple rules to stay ahead of rising customer demand and tighter customer expectations:

- Track what you own. Good inventory management starts with clean bins and clear counts. An easy‑to‑use inventory management software will watch your store inventory, flag low stock, and speed every order fulfillment process. When you can process orders fast, shoppers notice.

- Pick the right help. Some brands stick with own fulfillment. Others hire a fulfillment company that offers full ecommerce fulfillment services. You can even blend both with third party fulfillment for overflow. Match your fulfillment strategy to where and how you sell.

- Map your moves. More sales channels mean more steps in the supply chain. List each step—from cart to doorstep—and note who handles it. Clear maps cut hidden fulfillment and shipping costs and keep the shipping process on time.

- Think past borders. Planning to ship overseas? Check international fulfillment rules, duties, and carrier fees before you flip the switch. Smart prep trims international shipping delays and saves money.

- Place stock where buyers live. If half your customer orders come from the West Coast, add new fulfillment center locations there. Shorter routes lower postage and speed delivery, boosting customer experience and long‑term business growth.

Special Use Cases

- 📦 Subscription fulfillment: Deliver boxes on the same day each month. Consistent packing beats late surprises.

- 🖨️ Direct order fulfillment from your ecommerce platform: Many platforms now let you print labels in one click. This keeps ecommerce order fulfillment under your roof and under budget.

- 🚚 Efficient bulk drops: High‑volume online shopping days—think Black Friday—call for pre‑built pick lists so you can ship orders in waves to every customer place without chaos.

How One Seller Made the Switch to Rollo—and Never Looked Back

When a small business owner needed a hassle-free shipping setup, they turned to the Rollo Wireless Label Printer—and found more than just a sleek design. The compact printer fit right on their desk, required no special labels, and even connected to every device in their house, including their phone.

But what sealed the deal?

💬 “I reached out to Rollo… and within minutes I was talking to a real-life human being who walked me through the setup.”

This hands-on support, combined with fast wireless printing and flexible paper use, made Rollo their everyday go-to for shipping. Today, the printer hasn’t left their desk—and neither has their trust in Rollo.

Final Words

Fulfillment doesn’t have to chew through a third of every sale. Swap ink‑hungry printers for Rollo’s wireless thermal unit, batch labels in one click, and tap 90 % carrier discounts—all while keeping every box under your roof. You’ll ship faster, spend less, and own the customer experience from click to doorstep. Ready to see the difference? Try Rollo Ship free and turn shipping costs into growth fuel for your store, not overhead—ever again!

Follow Rollo on:

Ecommerce Fulfillment FAQs

📌 Q: What does an ecommerce fulfillment center do?

💭 A: It’s a big warehouse for online stores. Workers receive your products, put them on shelves, pick the right items when an order comes in, pack the boxes, ship them, and handle returns. They keep inventory up to date so customers get the right items fast.

📌 Q: How much does ecommerce fulfillment cost in 2025?

💭 A: Add up storage, picking, packing, and postage, and it usually costs about $12–$18 for each U.S. order. Extra fuel fees and returns can push the price higher. Using cheaper labels and the best carrier rates can cut that bill by around 30 %.

📌 Q: Is outsourcing fulfillment cheaper than in‑house?

💭 A: Paying a third‑party company saves you from buying shelves and forklifts, but they charge fees on every order. Handling orders yourself keeps full control but needs space and staff. Many stores mix both: they ship normal orders at home and send busy‑season overflow to a partner.

📌 Q: How can I automate label printing for my online store?

💭 A: Connect your store to Rollo Ship. Import your online orders, and the app groups them automatically. A wireless thermal printer then spits out one label per second. Your inventory system updates at the same time, so you save clicks and avoid mistakes.

📌 Q: When should I add multiple fulfillment centers?

💭 A: Add another warehouse when shipping takes too long, costs jump for far‑away zones, or global orders keep growing. Storing products in more places speeds delivery, lowers risk from local problems, and keeps customers happy—just be sure each center handles at least 500 orders a month to stay cost‑effective.

📌 Q: What’s the best way to organize order fulfillment as a small online seller?

💭 A: The best way is to keep fulfillment simple, consistent, and automated. Start by setting up a clear 5-step workflow: track inventory in real time, batch similar orders, use right-sized packaging, print shipping labels with a thermal printer, and connect to multi-carrier software like Rollo Ship. This keeps costs low, speeds up delivery, and prevents mistakes—making small sellers look as professional as big brands.