Print custom labels by using online design tools, blank label sheets, or professional printing services. Options range from DIY printing with inkjet, laser, or thermal printers to outsourcing rolls or sheets for larger volumes. The best method depends on your budget, quantity, material, and whether labels are for products, promotions, or shipping.

You’ve nailed the product. The box looks good. But when the first order hits the table, that plain sticker feels… flat. Print custom labels and the whole unboxing changes: your logo pops, details are clear, and the package finally looks like your brand. This guide shows small businesses how to design, print, and ship labels that look professional without draining time or budget.

Topic Highlights

What does it mean to print custom labels?

To print custom labels is to design and produce personalized labels that match your brand—logo, colors, product info, and barcode or QR code labels—then output them as printed labels on roll labels, sheet labels, or sticker sheets** for packaging, shipping, and promotions.

Custom labels are more than stickers. They’re tiny billboards. Unlike generic blanks, customized labels carry your story, ingredients, dates, and care notes in a compact format. They lift brand visibility, reduce returns, and make reorders easier for customers who can recognize your brand at a glance.

Why small businesses should print custom labels

Small businesses should print custom labels because it helps them look polished, earn trust, and move faster. They add a professional finish to packaging, reduce pick/pack errors, and keep compliance info front and center. Done right, labels become a growth lever—supporting promotion, business mailings, and smoother checkout** experiences online and in-store.

Think of labels as the handshake on every purchase. A clear logo, readable label size, and smart color choices help new shoppers “get” your product in seconds. Add a short benefit line. Add storage tips. Add a scannable code to tutorials or warranty pages. That’s helpful, trackable, and repeatable.

Types of custom labels and formats

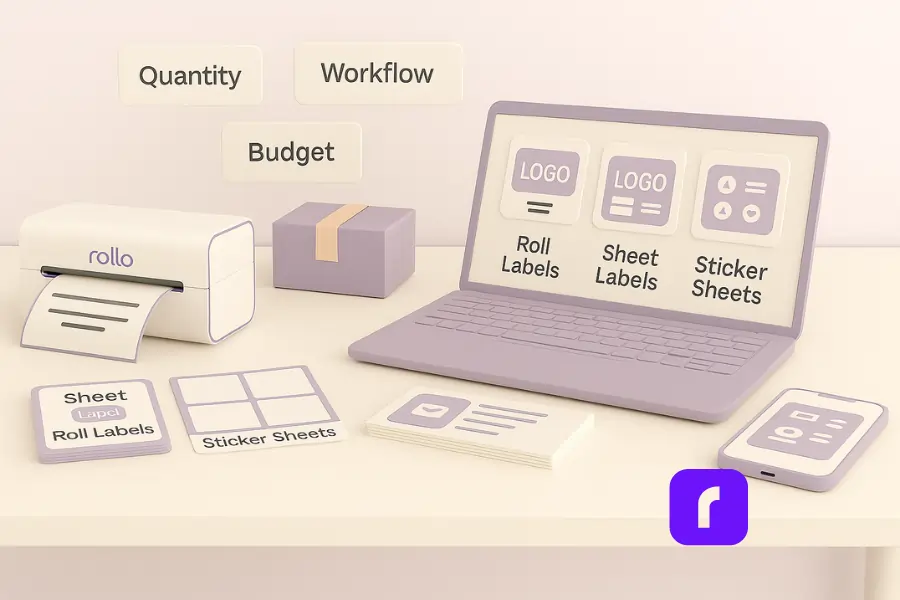

You’ll choose among roll labels, sheet labels, and sticker sheets. Rolls are efficient for larger volumes and dispensers. Sheets work for short runs and hand application. Sticker sheets are flexible for mixed designs or test batches. Pick the format that fits your quantity**, workflow, and budget.

Roll Labels vs. Sheet Labels

Rolls suit continuous runs, label applicators, and consistent standard sizes—great for scaling. Sheets fit desktop workflows, easy reprints, and mixed designs per page. If you print weekly or use a dispenser, choose rolls. If you test often, sheets are simpler.

Roll labels reduce reload time and help you stay consistent across SKUs. They’re ideal when you keep stock of core sizes and print daily. Label sheets help when designs change often, or when you’re iterating—holiday flavors, limited drops, or temporary promotion codes.

Sticker Sheets & Blank Labels

Sticker sheets are perfect for variety packs, brand kits, and sample runs. Blank labels let you print custom stickers on demand with inkjet or laser printers. They’re handy for seasonal packs, pop-ups, and sudden retailer requests where you need speed, not minimums.

Sticker sheets also help you create small “thank you” stickers or review prompts. Your shop can tuck one into each order. It’s a low-cost way to promote social follows or a new flavor drop without reprinting the main product label.

When to use each format to print custom labels

Use rolls to print custom labels for a steady output, label applicators, or warehouse teams. Use sheets to print custom labels for short runs and frequent design changes. Use sticker sheets for mixed packs, brand kits, and marketing inserts. Match format to quantity, materials, and standard production time** so you stay fast and under budget.

Quick picks:

- 📦 Shipping labels: Rolls (4×6) or sheets, depending on printer

- 🎁 Product packaging: Rolls for scale; sheets for new SKUs

- 🎉 Promos & freebies: Sticker sheets for variety and speed

Choosing the right materials to print custom labels

The right materials affect durability, cost, and feel. Use premium materials for display, laminated finishes for moisture, gloss for pop, and matte for a natural look. Food or bath goods may need water-resistant paper or film. Sustainability? Choose FSC-certified, BPA-free thermal label sheets.

Material menu (simple and effective):

- 📄 Paper: Affordable, print-friendly, wide standard sizes

- 💧 Film (BOPP/Vinyl): Water-resistant, flexible, great for bath/beauty

- 🛡️ Laminated finishes: Extra protection; wipeable surfaces

- ✨ Matte vs. Gloss: Matte feels modern; gloss adds shine

Tip: If the product sweats (cold chain, condiments), test a sample pack first.

How to design and print custom labels

Print custom labels by starting with your label size and shape, then build the artwork. Keep the logo readable, set bleed/safe areas, and export a high-res file. Upload your design, request a free digital proof, and print with inkjet, laser**, or thermal. For most e-commerce workflows, thermal is faster and cleaner.

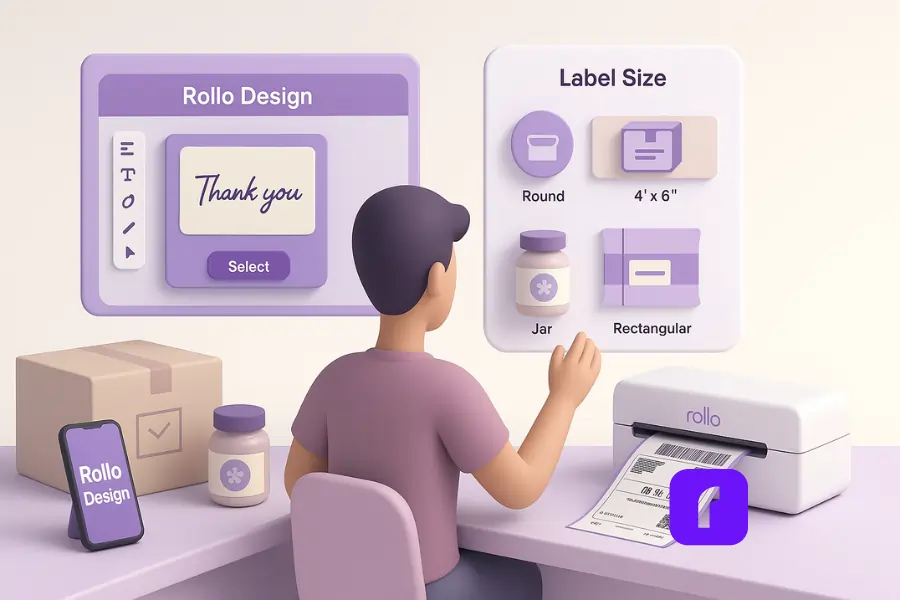

Label size, shape, and format

Choose standard sizes when possible. They’re cheaper and in stock more often. Match shape to your container or surface. Round labels soften; rectangles maximize info. If you hand apply, avoid micro labels. If you machine apply, choose precise gaps and rolls** that fit your applicator.

Fast sizing tips:

- 🚚 Shipping: 4×6 is the universal workhorse

- 🫙 Jars & tins: 2–3 inch rounds are reliable

- 🛍️ Pouches: Tall rectangles for ingredients + story

- 🔒 Caps/seals: Narrow bands or tamper tabs

Artwork, upload, and proofing

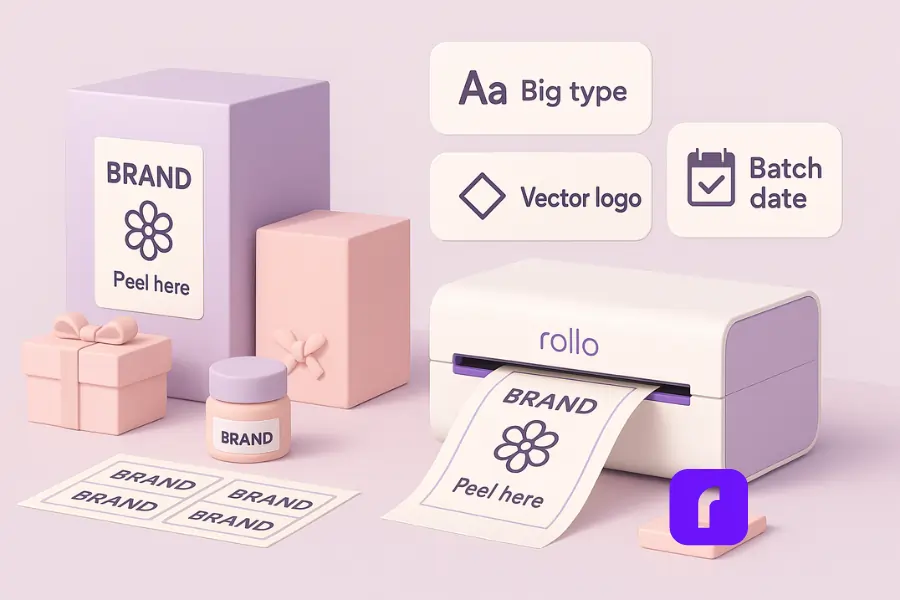

Keep font size large enough to read in poor light. Use vector logos. Export CMYK PDFs or high-res PNGs. Upload your file, request a free digital proof, and approve only after checking bleed, barcodes, and color shifts. If available, request free samples or a sample pack** to test surfaces.

Before final proof, print a one-page mock on office paper and tape it to the container. Check glare, curve distortion, and where fingers land. That three-minute test saves wasted sheets and reprints.

Print custom labels yourself vs. professional printing

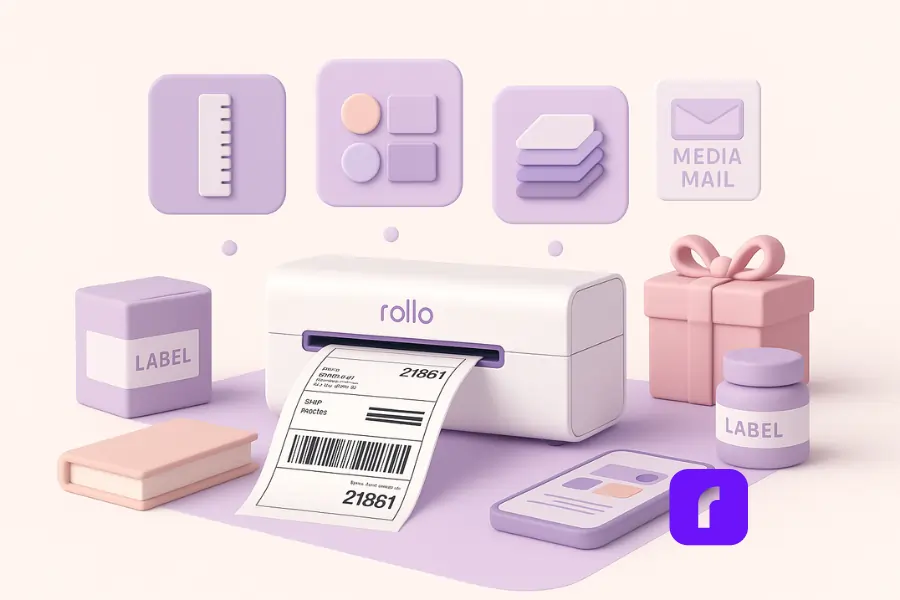

Laser printers and inkjet handle short runs and quick edits; beware ink costs and smearing. Professional shops offer films, foils, die-cuts, and spot finishes, but add business days and sometimes an additional fee for rush. Thermal printing gives small businesses clean, ink-free output with fast standard production time for shipping and product stickers. If you ship recurring packages, a wireless portable printer is a game-changer for subscription boxes.

How Rollo helps print custom labels:

- 🎨 Rollo Label Design App: Templates, custom sizes, and guided margins

- ⚡ Rollo Wireless Printer: Fast, ink-free labels for shipping and product use

- 📦 Rollo Ship: Discounted USPS & UPS rates plus printing in one place

By combining these tools, Rollo makes it easy for small businesses to print custom labels that look professional, save time, and streamline shipping operations.

Cost considerations for printing custom labels

Cost depends on quantity, materials, size, finish, and lead time. Standard sizes are cheaper. Larger volumes lower cost per label. Shops may charge setup and die fees, plus rush additional fee. Testing with a sample pack and approving a free digital proof** prevents costly remakes and delays.

Cost levers you control:

- 📏 Pick standard sizes and common cores (1″ or 3″)

- 🗂️ Group SKUs on sheets when artwork is similar

- 🎨 Keep colors simple; avoid heavy ink coverage on home printers

- 🔥 Use thermal for shipping and utility labels to skip ink entirely

Shipping note: If you outsource, pad timing by a few business days. Selling books or media? USPS Media Mail can cut your costs while still delivering reliably.

How custom labels boost business operations

Labels speed up receiving, picking, and returns. Add barcodes or QR code labels to route items, verify quantity, and reduce errors. On the customer side, a small personal sticker in the box boosts delight and promotion** sharing. Better labels make warehouses faster and unboxing more memorable.

Operational wins you’ll feel:

- 📦 At receiving: SKU stickers prevent mis-slots

- 🎯 At packing: Color cues cut pick mistakes

- 🔄 At returns: Scan codes route items to refurb or stock

- 📑 At marketing: Branded inserts and “how-to” mini labels reduce support tickets

Pair labels with Rollo Ship to print postage, compare rates, and keep labels + shipping in one simple flow.

Best practices for printing custom labels

Keep designs simple, test on the real surface, and stick to standard sizes when budget matters. Approve a free digital proof. If you sell anything splashy or cold, pick laminated** or film. For on-brand speed, build a repeatable file template and naming convention.

Checklist (save this):

- 🔠 Big type, short copy, clear benefit

- 🖼️ Vector logo, high-res art, defined bleed

- 🎨 One hero color, one neutral, plenty of white space

- 🏷️ “Peel here” cues for fast hand application

- 📅 Fresh batch date or lot code area

- 🔗 A tiny CTA: review link, recipe, or tutorial

Want even more time-saving tricks? Check out these custom label printing hacks that small businesses use to simplify design and speed up production.

Real-world examples of custom label success

A cotton-candy startup used sticker packs and 4×6 labels to unify craft packaging; reorders jumped because customers could find the flavors later. A keepsake brand used printed labels and thank-you stickers** to “sign” each box; support tickets dropped as care steps were printed right on the insert.

Example 1: Event sprint, zero stress A food cart planned a three-day festival. With sticker sheets, they ran a bright promotion code, batched flavors on sheets, and reprinted mid-day. No downtime. No minimums.

Example 2: Wholesale polish on a small budget A boutique soap maker switched to roll labels with a soft-touch film and clear gloss spot for the logo. The package looked premium, and retailers finally took notice.

Final Words

If you want packages that look as good as what’s inside, print custom labels. Choose the right materials, match the format** to your workflow, and keep designs simple and readable. Use thermal for speed and shipping, and save ink for marketing prints.

Beautiful labels aren’t luck. They’re process. With Rollo’s wireless printer, eco-friendly thermal labels, and the Rollo Ship app, you can customize fast, print clean, and ship smarter—without juggling tools. Ready to find your perfect label process? Try Rollo Ship free and put your next label project on rails.

Follow Rollo on:

Frequently Asked Questions About How to Print Custom Labels

📌 Q: Can I print custom labels at home without special gear?

💭 A: Yes. Use blank labels on inkjet or laser printers for small runs. For speed and clean edges, a thermal printer handles 4×6 shipping and utility stickers without ink.

📌 Q: What label size should I use for shipping packages?

💭 A: Most carriers expect 4×6. That size scans well, fits common boxes, and prints fast on rolls or sheets. It’s the safest default for shipping.

📌 Q: How long does outsourced label printing take?

💭 A: Expect a few business days plus standard production time. Rushed jobs may include an additional fee. If timing is tight, print in-house and reorder professionally later.

📌 Q: Are free samples or proofs worth it?

💭 A: Absolutely. A free digital proof catches bleed and color issues before you commit. A sample pack or free samples help you test surfaces and adhesion.

📌 Q: What’s the cheapest way to print custom stickers for promos?

💭 A: Use sticker sheets on a home printer or a short-run service. Keep colors simple and gang multiple designs per page. For shipping and utility tasks, go thermal to skip ink costs.