Shipping and receiving software helps you manage outgoing shipments and incoming packages in one place. It automates labels, syncs orders, and tracks inventory in real time. These tools connect with USPS, UPS, and stores like Shopify, cut errors, save minutes per order, and can lower shipping costs by up to 40%.

“Why does shipping always feel more expensive than it should be?” That’s a question plenty of small business owners ask when they see their carrier bill. The truth is, without the right shipping and receiving software, sellers often miss out on instant savings hidden in rates and workflows. This article shows how modern tools simplify labels, track inventory, and slash costs so your margins stay protected.

On This Page

What is shipping and receiving software?

Shipping and receiving software runs your outgoing and incoming orders in one place. It connects to your e-commerce stores, prints shipping labels automatically, and pulls inventory data. It also updates inventory records and shipment status in real time. The payoff: smoother order fulfillment, lower shipping costs, and fewer “Where’s my package?” emails.

Definition & core functions

Think of it as the hub that coordinates shipping services and the receiving process. It gathers inventory data from existing systems, prints labels, tracks delivery, and logs receipts with barcode scanners. You manage orders, capture order routing and quality checks, and keep stock levels accurate without bouncing between tabs.

- 🚚 Automating shipping: label creation, carrier selection, pickup scheduling

- 📦 Receiving operations: barcode scanning, putaway, cross docking when needed

- 🔄 Real-time updates: inventory movement and shipment statuses across channels

How it differs from a warehouse management system (WMS)

A warehouse management system is broader warehouse management software covering slotting, labor planning, and advanced warehouse operations. Shipping and receiving software focuses on the fulfillment process—rate shopping, labels, tracking, and receipts. Many SMBs start here, then add WMS features as volume grows. You can integrate both for end-to-end control.

Who needs it?

If you ship five orders a day or five hundred, you benefit. Online sellers, small warehouses, and growing brands use it to track inventory, reduce errors, and gain real time inventory visibility. It’s great value for teams without IT staff who need dependable tools that just work.

How does shipping and receiving software work?

It connects to your store, pulls orders, and runs shipping automation to pick the best service at the best carrier rates. It prints labels, updates tracking, and pushes real time visibility to customers. On the receiving side, it logs purchase order receipts, verifies quantities, and updates inventory levels instantly.

Shipping automation features

Automation rules handle carrier selection, package type, and insurance—no more guesswork. The software compares shipping rates across more carriers, applies special rates, and triggers best shipping rates based on weight, zones, and delivery promise. That’s accurate labels, fewer clicks, and instant savings without spreadsheets.

In fact, 63% of shoppers now expect three-day shipping as standard, and 40% won’t shop with brands that don’t offer it. Automating carrier selection helps small businesses meet those delivery promises without eating into margin.

- 💸 Rate shopping across shipping carriers (USPS, UPS, and FedEx)

- ⚙️ Auto-apply rules by SKU, customer tag, or destination

- 🖨️ Batch labels for busy days; reprint in one tap

Receiving operations that keep stock honest

Receiving software integrates with your catalog and purchase order data. When incoming shipments arrive, you scan barcodes, confirm counts, and record damages. The system posts inventory records and real time visibility back to your store, so what customers see matches what’s on the shelf.

- 📷 Barcode scanning for speed and accuracy

- 🗂️ Putaway prompts to the correct bin or shelf

- ⚡ Cross docking to speed delivery on hot items

Order fulfillment processes, simplified

From pick lists to label print to handoff, the system guides each step. You get order accuracy, fewer mis-picks, and cleaner delivery estimates. If an item is short, it flags a backorder and alerts the buyer. Your team can manage orders without sticky notes or guesswork. Smart software guides every step, from pick lists to final handoff. If you want a deeper dive into building a smooth process, check out our order fulfillment guide.

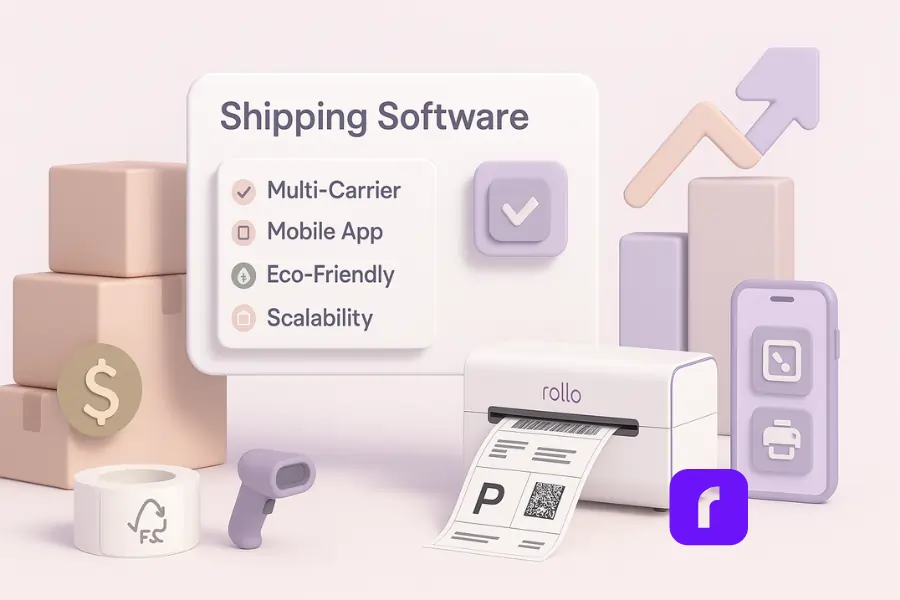

What are the key features of shipping and receiving software?

Look for multi-carrier support, bulk label printing, barcode scanning, and real time updates that sync with ecommerce platforms. Strong reporting gives valuable insights for decision making: cost per shipment, on-time delivery rates, and error trends. If it’s feature rich but still easy, you’ll actually use it every day.

Shipping features that save clicks

Core shipping features include label automation, carrier integrations, and pickup scheduling. Advanced platforms add order routing rules, return labels, and international paperwork. The more you automate, the less you pay in labor costs—and the fewer mistakes you ship.

- 🏷️ Labels in batches; auto-choose service level

- 💲 Commercial pricing access; best carrier rates

- 🔁 Return workflows that don’t derail your day

Receiving features that keep counts correct

Receiving features should make it simple to unload, check, and put away. Scan cartons, confirm counts, and note defects fast. The system updates inventory systems and triggers alerts if a supplier short-ships. You get cleaner counts, fewer tickets, and faster re-stock.

- 📑 ASN and purchase order match

- 📸 Condition notes and photos at dock

- 🛒 Guided putaway for faster warehouse operations

Inventory management that’s actually usable

You want clear stock levels, aging reports, and low-stock alerts that your team actually reads. Real time inventory visibility keeps listings accurate, prevents oversells, and smooths the fulfillment partners handoff. A good dashboard shows where items live and when they’ll run out.

Analytics & visibility you can act on

Reports should answer simple questions: What did shipping cost? Which services miss delivery? Where do errors happen? Use cost and performance charts to guide decisions, then tweak automation rules. Over time, small changes add up—minutes per order reclaimed and meaningful percent savings on postage.

How much does shipping and receiving software cost?

Pricing ranges from free tiers to monthly subscriptions to pay-as-you-ship. Watch for add-ons like API access, user seats, and premium support. Hardware matters too—label printers and mobile devices. The right fit balances predictable cost with clear savings on postage and time.

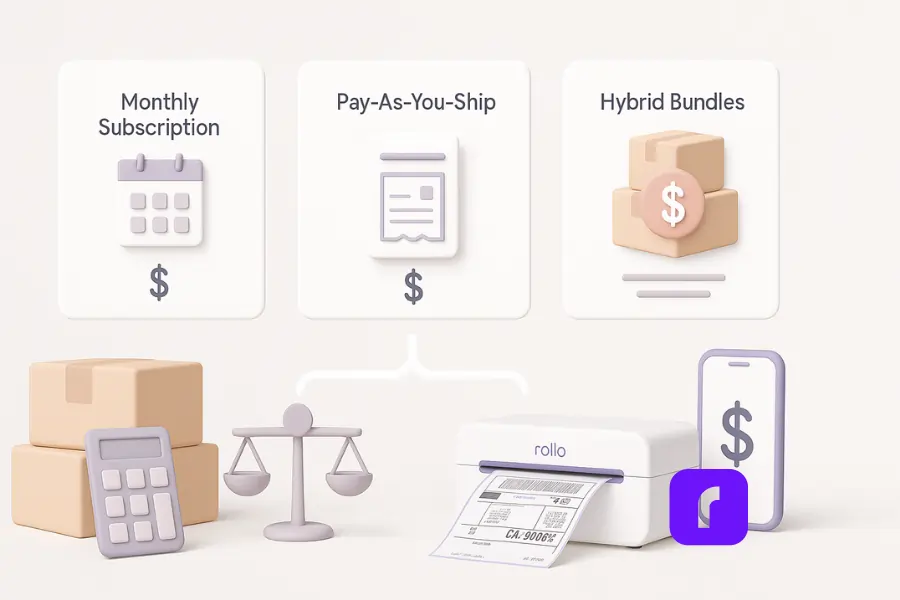

Common pricing models

You’ll see three patterns: monthly plans with caps, per-label fees, and hybrid bundles. Monthly works if volume is steady. Per-label fits seasonal sellers. Hybrids offer special rates plus features. Always map plan tiers to your order curve.

Hidden costs to watch

Beware of charges for custom integrations, extra warehouses, or advanced automations. Some platforms meter API calls or limit shipments per month. Ask about implementation fees, label reprint charges, and international forms. A quick spreadsheet of “all-in cost” saves painful surprises later.

Affordable options for SMBs

If you’re volume-light, start with a free plan or pay-as-you-go. As you grow, step into a plan that unlocks better carrier rates and advanced features. Make sure you can export data easily if you switch later.

How does shipping and receiving software save time and money?

Automation compresses every step: fewer clicks, faster print, cleaner counts. Rate shopping chooses a cheaper service automatically, while bulk printing shaves minutes from each batch. On the receiving side, scanning cuts errors that lead to reships. Over a month, the savings stack up.

Minutes saved per order

Labels in one click. Pick lists sorted by aisle. Reprints without hunting a PDF. Sellers regularly reclaim several minutes per order—more during peak. That’s hours back each week for support, listing, or, you know, lunch.

- 🖨️ Batch print by carrier or SKU

- 🔄 One-tap reprints when a label smears

- 📂 Auto-archive paperwork to stay organized

Error reduction that protects margin

Mis-picks, wrong weights, and bad addresses eat profit. With barcode scanning and service validation, you reduce errors before they ship. On the dock, receiving features catch shortages and damages immediately, so purchase order claims are simple and fast.

And it’s not just fulfillment mistakes—support costs add up too. WISMO requests (“Where is my order?”) can account for up to 50% of all support calls, and each ticket costs about $12 to resolve. Reducing errors and providing real-time updates means fewer tickets, lower costs, and happier customers.

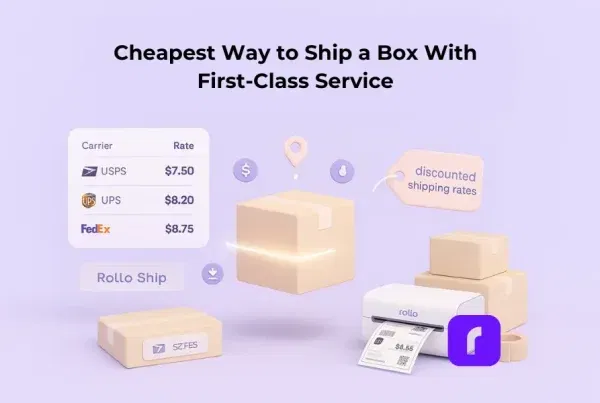

Shipping discounts without phone calls

Platform-level discounts and special rates bring instant savings without negotiating with carriers. Combine that with best shipping rates logic, and you pay less for the same promise. You won’t win every shipment, but you’ll win far more than you do by hand. Many platforms secure discounted USPS and UPS rates automatically, which adds up for resellers handling daily orders. See how resellers unlock extra savings with shipping apps to maximize margins.

⚡ Shipping and Receiving Software for Instant Savings

Sync orders, compare USPS and UPS rates, print 4×6 labels in seconds, and track inventory in real time. Cut costs and reduce errors today.

What should small businesses look for in shipping and receiving software?

Look for fast setup, clean UI, and reliable printing. Must-haves: multi-carrier support, strong integrations with ecommerce platforms, and real time updates on orders and inventory. Bonus points for mobile devices support and sustainable supplies. If your team smiles during training, you picked well.

Ease of integration

Connect your store in minutes, not days. Check that your marketplaces, carts, and accounting tools are supported out of the box. If you need custom integrations, confirm the path and cost up front so you’re not blocked at peak.

Scalability without stress

Can it handle seasonal spikes and more carriers? Will it add another warehouse cleanly? A good system scales features and users without a ticket to support. You shouldn’t need a full-time admin to keep shipments moving.

Mobile devices and on-the-go workflows

Phones and tablets belong on the floor. Approve orders, scan, and print from mobile devices. Quick actions, big buttons, and offline-friendly design make busy days safer and faster.

Sustainability and supplies

Small choices add up: eco-friendly labels, smarter packaging, and routes that reduce miles. Use FSC-certified, BPA-free labels and right-size boxes. Cost goes down, waste goes down—it’s a win both ways.

Does Rollo offer shipping and receiving software?

Yes. Rollo Ship helps sellers automate labels, compare carrier rates, and sync orders with real time visibility. Pair it with the Rollo Wireless Label Printer for quick, ink-free prints and FSC-certified, BPA-free labels. It’s built for small businesses that want instant savings without heavy setup.

Rollo Ship benefits for SMB sellers

Rollo Ship connects to major ecommerce platforms, supports more carriers, and handles rate shopping automatically. You get transparent pricing, quick setup, and reporting that surfaces valuable insights. It’s feature rich without the training burden.

- 💡 Auto-apply best shipping rates by rule

- 📊 Clean dashboard to manage orders and returns

- ✅ Clear metrics for decision making

Rollo Wireless Label Printer

Fast, reliable, and ink-free. Print crisp shipping labels from desktop or phone in seconds. Wireless means fewer cables on the bench and less downtime. It’s the dependable tool you reach for on every batch. A reliable printer matters just as much as smart software. Our guide to shipping printer advantages shows why the right device can shave minutes off every batch.

🖨️ Print Shipping Labels Fast With Rollo Wireless Printer

Create crisp 4×6 labels in seconds—ink-free, reliable, and scan-ready for every shipment. Pair it with shipping and receiving software for instant savings.

Eco-friendly labels that look sharp

Rollo’s FSC-certified, BPA-free thermal labels feed cleanly and stick well. They’re durable on the move and kinder to your pack-station air. Sustainable supplies that don’t slow you down.

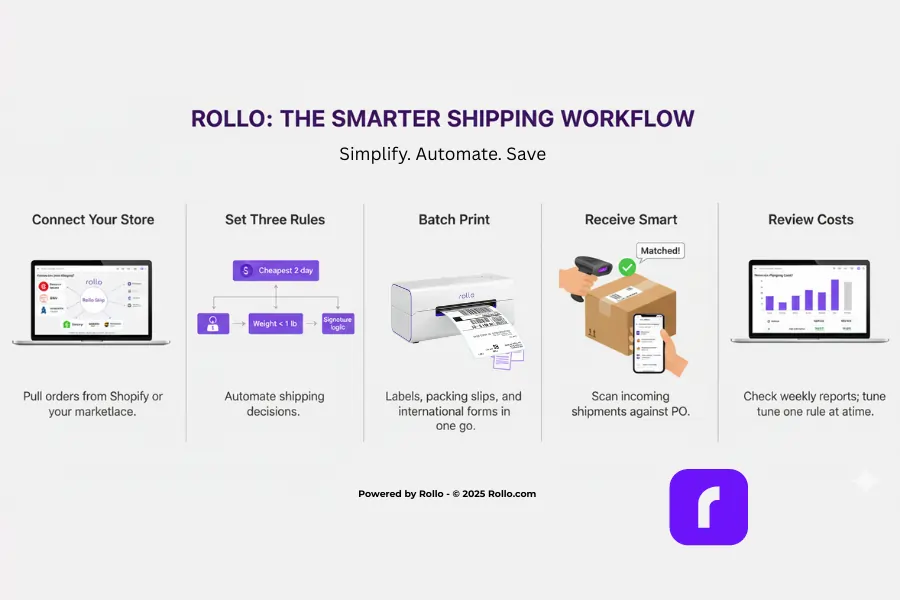

Rollo: The Smarter Shipping Workflow

Running shipping by hand wastes time and cuts into your profit. With Rollo, you can set up a smooth system that keeps orders moving and mistakes out of the way.

- Connect your store. Pull orders from Shopify or your marketplace.

- Set three rules. Cheapest 2-day, weight under a pound, and signature logic.

- Batch print. Labels, packing slips, and international forms in one go.

- Receive smart. Scan incoming shipments against the purchase order.

- Review costs. Check weekly reports; tune one rule at a time.

Each step gives you back minutes on every order. Over weeks and months, those minutes add up to hours saved and instant shipping discounts—so you can spend less time stressing and more time selling.

Final Words

You don’t need a massive warehouse management system to ship like a pro. A focused shipping and receiving stack—labels, automations, and clean receiving—delivers instant savings and calmer workdays. Start simple. Get the basics right. Then let the software handle the boring parts while you grow the business.

Follow Rollo on:

Frequently Asked Questions About Shipping and Receiving Software

📌 Q: What’s the difference between shipping software and a WMS?

💭 A: Shipping software handles labels, tracking, and receipts. A WMS manages space, labor, and advanced warehouse logic. Many SMBs start with shipping and receiving software, then add WMS features as volume grows.

📌 Q: Is it hard to integrate with my store?

💭 A: Most platforms connect to Shopify, Amazon, TikTok Shop, and eBay in minutes. If you use something custom, ask about connectors or APIs before you buy.

📌 Q: How fast can I see savings?

💭 A: Often on day one—rate shopping finds cheaper services you already qualify for. Add automation rules and batch printing, and you’ll shave minutes off each batch, too.

📌 Q: Can one system track both shipping and receiving?

💭 A: Yes. Look for receiving features tied to purchase orders, barcode scanning, and instant inventory updates. That keeps counts accurate and orders honest.