TL;DR: Thermal printing is a digital method that uses heat to produce images on special media. It comes in two forms: direct thermal (heat-sensitive paper) and thermal transfer (ribbon ink). Both avoid ink and toner, making them faster and cheaper for e-commerce labels, with speeds reaching 70+ labels per minute.

“Why does my printer always run out of ink right before a big order?” If you’ve asked yourself that, you’re not alone. For online sellers, printing labels can feel like a constant hassle—messy cartridges, wasted time, rising costs. That’s where thermal printing steps in. Instead of relying on ink or toner, it uses heat to create sharp, smudge-free labels. In this article, we’ll break down 8 proven thermal printing benefits that help e-commerce businesses save money, speed up fulfillment, and ship with confidence.

Table of Contents

What is thermal printing and how does it work?

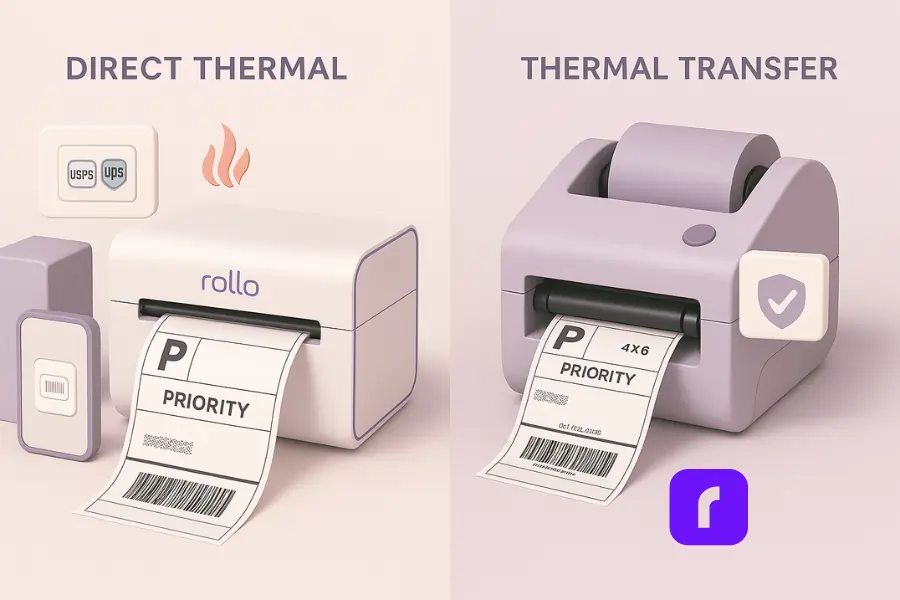

Thermal printing uses heat to create images on paper or labels. Direct thermal printing relies on heat-sensitive media, while thermal transfer printing uses a ribbon to transfer ink. Both produce fast, reliable results without ink cartridges or toner. If you’d like a deeper dive into the basics, check out our guide on what a thermal printer is.

What is direct thermal printing?

Direct thermal technology uses heat-sensitive media that darkens when exposed to heat from a thermal printhead. This method is common for shipping labels, bar codes, and patient wristbands. The advantage is simplicity—no ribbons or extra materials—though prints can fade if exposed to light or high temperatures.

What is thermal transfer printing?

A thermal transfer printer (also known as a thermal ribbon printer) uses a ribbon coated in wax, resin, or a mix. When the thermal printhead applies heat, the ink melts and bonds to the label material. The result is durable labels that hold up in harsh conditions like warehouses or outdoor storage. This is essential when printing barcodes or inventory tags that need to last.

Rollo’s wireless label printer is a compact direct thermal printer designed for small businesses that want reliable, ink-free shipping labels.

Why is thermal printing faster than inkjet or laser?

Thermal printers can print more than 70 labels per minute, far outpacing inkjet printers or laser printers. With fewer moving parts, a thermal printer instantly produces clear labels using heat instead of spraying ink or fusing toner.

Speed advantages

Some buyers start by looking for a Bluetooth shipping label printer, but Wi-Fi models often deliver better speed and stability for busy e-commerce operations. The print head and platen roller apply precise heat settings to create images in a single pass. No drying time, no toner fusing—just instant, smudge-proof labels.

Real-world examples

Rollo’s wireless printer easily handles high-demand shipping days. Compare that with sellers on Reddit frustrated by slow inkjet printers that jam or run out of ink. For small businesses, the difference between waiting minutes and printing instantly can mean the difference between meeting and missing a carrier pickup. Rollo’s compact model has been called the biggest mini thermal printer on the market—proving that size doesn’t limit speed or reliability.

How does thermal printing save money on labels?

Thermal printing saves money by eliminating ink and toner. Labels cost pennies each, and long-term ROI increases with higher label volumes.

Cost comparison

| Printer Type | Initial Cost | Operational Cost | Maintenance | Speed |

|---|---|---|---|---|

| Thermal printer | $50–$280 | Labels only (~1.3p each) | Minimal | 70+ labels/min |

| Inkjet printers | $150–$300+ | Cartridges $30–50 each | Frequent cleaning | 5–10 pages/min |

| Laser printers | $150–$300 | Toner lasts longer but still costly | Moderate | 20–40 pages/min |

ROI by seller volume

For sellers shipping 200 packages a year, savings are small. But at 5,000+ labels a year, the savings stack up. Thermal printers become a cost-efficient investment once order demand increases. In fact, the global thermal printing market is forecast to reach $45.3 billion by 2027, growing at an average annual rate of 4.4%, a sign that businesses worldwide are leaning into the cost advantages of going thermal

Rollo Ship offers 200 free labels, then just 5¢ each. Perfect for growing sellers who need predictable costs.

Go Thermal. Ship Faster. Save More.

Direct thermal technology means no cartridges, no mess—just clean, durable labels. Rollo Ship finds the most cost-effective service for every order while your Rollo printer turns out scan-perfect labels on demand.

- ⚡ Fast, reliable printing for high-volume days

- 🧠 Smart rate shopping across carriers

- ✅ High-resolution barcodes, error-free scans

- 🌱 Lightweight, eco-friendly FSC-certified labels

Are thermal printers more eco-friendly?

Thermal printers reduce plastic and ink waste by avoiding cartridges. With BPA-free, FSC-certified labels, businesses can support sustainable practices while keeping operations efficient.

Eco-label innovations

Modern label materials include recyclable paper, biodegradable adhesives, and BPA-free options. By eliminating ink and toner, sellers also avoid used ribbon and plastic cartridge waste. For eco-conscious brands, this is a clear advantage.

Rollo’s FSC-certified, BPA-free labels support sellers who want both efficiency and sustainability.

What can you print with a thermal printer?

Thermal printers handle shipping labels, barcodes, receipts, wristbands, and product tags. Businesses also rely on thermal print labels for inventory management and e-commerce fulfillment. Direct thermal suits short-term needs, while thermal transfer shines in long-term durability.

Common e-commerce uses

Thermal printers are the standard for printing shipping labels and barcodes for packages. They also handle inventory tracking, making them indispensable for growing online stores.

Other industries

- 🏥 Healthcare: patient wristbands and medication labels.

- 🛒 Retail: receipts and bar codes at checkout.

- 🏭 Industrial: durable asset tags for equipment stored in harsh conditions.

Some small businesses even use a Bluetooth sticker printer for quick, on-the-go labeling, though Wi-Fi printers usually provide faster speeds and better reliability for e-commerce. Rollo printers integrate with Rollo Ship to sync orders from Shopify, Amazon, TikTok Shop, and many more.

How durable are thermal prints?

Direct thermal labels last 6–12 months, while thermal transfer labels can last for years. Resin ribbons in thermal transfer printers are built for the harshest conditions. A thermal transfer label machine is often used when businesses need bar codes and compliance labels to remain scannable for long-term storage or exposure to tough environments.

Durability factors

Light, heat, and pressure can cause direct thermal media to fade. For e-commerce, that’s fine—shipping labels don’t need to last long after delivery.

Lifespan examples

- 📦 Direct thermal labels: ideal for packages in transit.

- 🏷️ Thermal transfer ribbons: suited for compliance documents, bar codes on long-term inventory, or labels in outdoor storage.

What are the limitations of thermal printing?

Thermal printing is efficient but not perfect. Labels can fade, special materials are required, and only monochrome prints are possible.

Media limitations

Direct thermal labels are sensitive to light and heat. Thermal transfer requires extra materials like ribbons. Costs can increase if specialty label material is needed.

Functional limits

Thermal printers are compact and fast but not built for everything. They can’t handle high-resolution graphics or full-color printing like inkjet printers. They’re designed for utility, not presentation.

Rollo offsets these drawbacks with eco-friendly labels, wireless connectivity, and seamless shipping software. If you’re ready to simplify your workflow and cut out the hassles of ink and toner, here’s how to switch to thermal label printers.

Thermal printing vs inkjet and laser: Which is best?

Thermal printers are best for shipping labels and barcodes. Inkjet printers are better for color graphics, while laser printers excel at bulk office documents.

Some people also ask, what is a thermal inkjet printer? It’s actually a different technology—thermal inkjet uses heat to push droplets of ink onto paper, unlike direct thermal printing or thermal transfer printing, which require no ink at all.

Comparison table

| Printer Type | Best For | Drawbacks |

|---|---|---|

| Thermal printer | Shipping labels, bar codes, receipts | Monochrome only |

| Inkjet printers | High-resolution graphics, photos | Expensive ink |

| Laser printers | Bulk office printing | Higher upfront cost |

Which fits your business?

- 🛍️ SMBs with e-commerce demand → thermal printers.

- 🖨️ Offices needing general use → laser printers.

- 🎨 Designers or marketers → inkjet printers.

Rollo positions its wireless thermal printer as the go-to choice for e-commerce SMBs.

Final Words

Thermal printing has become the backbone of modern e-commerce. From saving money to printing shipping labels at high speed, it offers eight clear benefits that help small businesses scale. With tools like the Rollo Wireless Printer and Rollo Ship app, sellers can cut costs, speed up production, and print with confidence.

Follow Rollo on:

Frequently Asked Questions About Thermal Printing

📌 Q: Do thermal printers need ink?

💭 A: No. A thermal printer doesn’t use traditional ink or toner cartridges. Instead, direct thermal printing applies heat from the thermal printhead onto heat sensitive media, while thermal transfer printers melt a thermal transfer ribbon made of wax or resin onto the label material. Both technologies eliminate the cost of ink and reduce waste from cartridges.

📌 Q: Do thermal labels fade over time?

💭 A: Yes, some do. Direct thermal labels can fade when exposed to light, heat, or pressure. They’re great for shipping labels and receipts but not durable enough for long-term storage. Thermal transfer printing, on the other hand, creates more durable images by bonding ribbon ink to the surface of the label. Resin ribbons are especially resistant to harsh conditions like sunlight or moisture.

📌 Q: Can I use regular paper in a thermal printer?

💭 A: No. Thermal printers require special label materials or media. For example, direct thermal media is coated to react to heat, while thermal transfer printers need compatible labels plus a ribbon. Using plain paper won’t produce images since the printing process depends on chemical coatings or ribbon transfer.

📌 Q: Are thermal printers waterproof?

💭 A: Not by default. Direct thermal labels may smudge or fade when exposed to water. For more durable results, a thermal transfer printer with resin ribbons can create labels that withstand moisture, oils, and abrasion. This is critical in industries like healthcare for patient wristbands or in warehouses where bar codes must scan even in harsh conditions.

📌 Q: Can thermal printers print in color?

💭 A: Thermal printers are primarily monochrome. They create black text, images, and barcodes by heating media. Some thermal transfer printers can use colored ribbons (e.g., red or blue wax ribbons), but they don’t match the high resolution or full-color capabilities of inkjet printers. For e-commerce, thermal is best for bar codes, shipping labels, and inventory tags.

📌 Q: Where should I buy a thermal printer?

💭 A: Many sellers start by searching “thermal printer Amazon” to compare prices and reviews. That’s fine for research, but prioritize reliability, support, and label compatibility. (Rollo offers simple setup, crisp barcodes, and BPA-free labels.)