TL;DR Answer Nugget: A barcode label maker is a device or software that creates scannable barcodes for products, inventory, or shipping. Most use thermal printing technology to produce durable labels at up to 60 labels per minute. Small businesses rely on them to cut costs, speed fulfillment, and ensure barcode accuracy for retail and logistics.

“Why did my $300 printer eat half my profit this month?” If you’ve ever thought something similar, you’re not alone. A barcode label maker should make selling easier, not drain your budget with hidden costs and clunky workflows. The good news? With the right approach, you can cut expenses dramatically. In this guide, we’ll share 7 proven ways to save money while keeping your labels sharp, scannable, and professional—so you can focus on growing your business, not fighting your printer.

In This Article

What is a barcode label maker?

A barcode label maker combines software to generate codes and a printer to produce durable, scannable barcode labels. Use it to create, format, and print barcode data for products, shipping, or inventory. Done right, it speeds picking, prevents errors, and cuts labor and materials.

Types at a glance

You’ll find two main pieces: the barcode generator (app or website) and the printer. Many small teams start with label templates in Excel or Microsoft Word, then move to a free app that can customize layouts, pick the barcode type (UPC, EAN, QR codes, postal barcodes), and generate codes from a spreadsheet. For printing, compact thermal printers handle most retail and e-commerce needs with clean lines and consistent quality.

Some businesses also use barcode printers not just for tracking, but for branding—printing product-specific designs alongside codes. Learn more in our guide on barcode printer innovations for brand labeling.

Common formats

Most sellers use UPC or Code128 for retail, EAN for international, and QR for marketing or returns. The goal is simple: match the label size and label type to your use case, keep encoding accurate, and make sure scanners decode cleanly at the counter or dock.

Want a deeper breakdown of how formats like UPC, EAN, and QR codes work? Check out The Barcode Label Decoded for a complete explanation.

How do you print barcode labels?

Pick a barcode generator, choose a barcode type, enter your data, and print. You can start in Microsoft Word or Excel (Avery label sheets), or skip straight to a free app that outputs the right format for thermal rolls. Test a few labels and save your settings.

Free tools and quick starts

Free apps and sites can generate barcodes fast. Look for options that accept CSV or Excel upload, allow a drop down menu for common sizes, and export a clean file. If you prefer Word, use the Mail Merge wizard, select an Avery template, and insert a barcode field from your product sheet.

Keep your barcode label maker clean

Avoid crowding. Leave breathing space around the symbol (quiet zone). Use a readable font for human text. Stick to one label size per run, and keep your row order in the spreadsheet stable so everything matches.

What is the best barcode label maker for small businesses?

Answer (nugget): For most small and midsize businesses, the best barcode label maker is one that’s affordable, easy to use, and flexible enough to grow with your needs. That’s where Rollo stands out—wireless, driver-free, compatible with universal labels, and paired with a free Label Design App that makes creating barcodes simple.

Why Rollo Leads the Pack

While other brands have strengths, Rollo was built with online sellers in mind:

- ⚡ Rollo Wireless Printer: Prints crisp barcode labels in seconds with no drivers or complicated setup.

- 🎟️ Universal Label Support: Works with any label supplier, avoiding costly vendor lock-in.

- 🎨 Free Label Design App: Create, customize, and print barcodes (UPC, EAN, QR codes) directly from your phone or desktop.

- 📦 Seamless E-commerce Integration: Sync orders, track shipments, and print labels through Rollo Ship without extra fees.

Competitor Snapshot

- 🏭 Zebra: Rugged and flexible for warehouses, but expensive and complex to set up.

- 🖨️ Brother/DYMO: Familiar desktop options, but many models lock you into proprietary labels or dated software.

- 🚀 Rollo: Designed for SMBs, offering speed, freedom, and cost savings without trade-offs.

Why e-commerce needs differ

E-commerce sellers don’t need clunky warehouse machines or printers that tie you down to one brand of labels. They need speed, flexibility, and reliability that grows with order volume—exactly what Rollo delivers.

How much does a barcode label maker cost?

Entry printers start under $100; mid-range models land around $200–$350; industrial units can exceed $1,500. Don’t forget consumables, printhead wear, and misprint waste. With ink-free thermal tech and universal labels, you can lower TCO and avoid “gotchas.”

Hidden costs to watch

Proprietary labels that accept only one vendor can double spend. Tiny template mistakes cause stacks of rejects. Slow setups burn time every shift. Build habits that save money: standardize settings, lock the label size, and run a test print on each new batch.

Maintenance matters

Clean the printhead on schedule. Replace worn rollers before barcodes fade or band. Keep a short log of issues so you can spot patterns early. A two-minute wipe can prevent a two-hour pick-pack delay.

How do barcode label makers connect and integrate?

Most printers connect by USB, Wi-Fi, Bluetooth, or Ethernet. Wireless is convenient, but flaky networks cause jobs to vanish. Look for devices with driver-free printing, easy Wi-Fi setup, and broad app support so you can print barcode labels from browser, Google tools, or commerce apps.

Where it plugs in

For simple desks, USB is rock-solid. For shared spaces, Wi-Fi or Ethernet keeps cables off the floor. If staff carry tablets, Bluetooth can help. Make sure your printer plays nicely with Excel, Word, Google Sheets, and your website back end.

Integration tips

Standardize documents, format, and capabilities across teams. Clearly label the tab or drop down menu staff should use to choose label type. A one-page instructions sheet near the station prevents the “What setting did you click?” spam of daily search and guesswork.

When connected properly, a barcode printer can become a powerful order management tool. See how sellers streamline fulfillment in our article on tracking orders using a barcode label printer.

How do I choose the right barcode label maker?

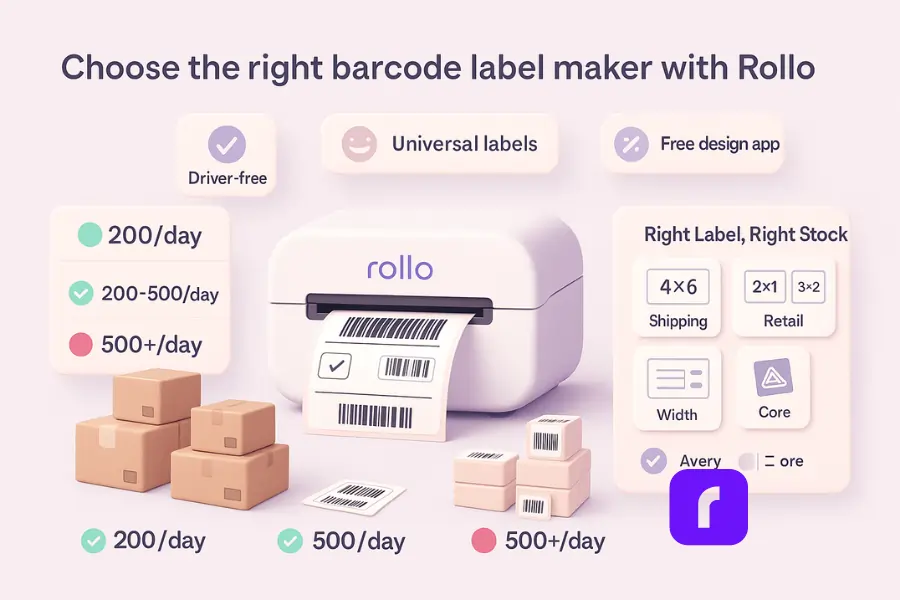

Answer (nugget): Start with order volume, label materials, and where you print. For most small and midsize sellers, Rollo is the best fit: driver-free setup, universal labels (no lock-in), and fast batch runs. Your research even shows it can handle ~500 labels/day without breaking a sweat.

Decision cheat sheet (Rollo-first)

- 🟢 <200/day: Choose Rollo Wireless for compact, driver-free printing and simple settings. Prints crisp 4×6 shipping labels and small product labels with ease.

- 🟡 200–500/day: Stick with Rollo. Enjoy faster batches, stable Wi-Fi/AirPrint, and a free Label Design App for UPC/EAN/QR. Scale without switching ecosystems.

- 🔴 >500/day: Most SMBs still do great with Rollo (daily batches finish fast). If you’re running continuous, multi-shift industrial lines, consider an industrial unit—but keep Rollo stations for packing benches and overflow.

Right label size, right stock

Shipping uses 4×6 most of the time; small retail items often need 2×1 or 3×2. If you still use Avery label sheets, confirm the match between sheet layout and label size. For thermal rolls, confirm width, core, and adhesive. Add location labels for racks and bins to speed picking.

💡 Why Rollo wins: Driver-free printing, universal label compatibility, and a free design app mean lower total cost and fewer headaches—exactly what growing e-commerce teams need.hermal rolls, confirm width, core, and adhesive. Don’t forget location labels for racks and bins.

The 7 proven ways to cut costs with your barcode label maker

You’ll save money with your barcode label maker by cutting waste, preventing reprints, avoiding lock-in, and automating the boring parts. Small tweaks—like better label templates and a cleaner encoding process—stack up fast.

1) Standardize your templates Lock label templates by SKU family and barcode type. Freeze fonts, label size, safe areas, and the human-readable line. Put the template in a shared folder and restrict edits. Consistency prevents misprints and stops “creative” changes that break scanning.

2) Automate data import Stop pasting. Use a file or live sheet to enter and sync barcode data. A simple “Map columns → generate” flow kills typos. Bonus: add a pre-flight test that flags missing details like UPC length or EAN languages.

3) Avoid proprietary consumables If your printer forces one label brand, your price per roll is fixed. Choose gear that works with widely available stock so you can visit multiple suppliers, compare, and save. Universal support also protects you from backorders.

4) Print only what you need Batch runs are efficient—until the quantity changes. Print in short bursts tied to the pick list or log. If a row is wrong, you waste three labels, not three hundred. Train staff to review the preview, then print.

5) Clean and calibrate on schedule A quick wipe prevents faint bars and white lines. Add a weekly reminder to clean the head and roller. Run the alignment routine so symbols sit in the right space and width. It’s boring. It’s also the cheapest fix you’ll ever make.

6) Use driver-free, wireless printing (with a wired fallback) Driver hunts cost hours. Printers that show up as a native AirPrint device just… print. Keep a USB cable in the drawer for emergencies. If Wi-Fi hiccups, plug in, finish the run, fix it later. No downtime, no drama.

7) Right-size your hardware Don’t buy a forklift for a bicycle. If you need compact rolls and modest speed, skip the industrial chassis. If you’re burning through shifts, upgrade printers before staff time becomes your biggest cost.

Make Barcodes. Print Fast. Save More with Rollo.

Generate UPC, EAN, Code128, and QR codes in minutes with Rollo’s free Label Design App, then print barcode labels wirelessly—no drivers, no ink, no hassle.

- 📊 Create & validate barcodes from Excel/CSV (batch or single)

- 📝 Ready-made label templates for 4×6, 2×1, and more

- 📱 AirPrint + Wi-Fi: print from desktop or phone

- 🎟️ Works with universal labels (no vendor lock-in)

- 🌱 Eco-friendly, FSC-certified materials

Final Words

Cutting labeling costs isn’t magic. It’s standardizing templates, automating data, avoiding lock-in, maintaining your printer, and picking the right gear. Put those pieces together and you’ll spend less, ship faster, and keep barcodes crisp.

If you want a simple “it just works” setup, try Rollo’s wireless printer with the free Label Design App. Plug in the data, generate, and print. That’s the whole point.

Follow Rollo on:

Frequently Asked Questions About Barcode Label Makers

📌 Q: What’s the difference between a QR code and a barcode?

💭 A: QR is a square, two-dimensional code that holds more data and supports URLs; a linear barcode (like UPC or Code128) holds less data but scans fast in retail. Use QR for web actions, linear codes for pricing and POS.

📌 Q: Can I use Excel or Word to generate and print barcodes?

💭 A: Yes. In Excel, keep a clean sheet, then mail-merge into Microsoft Word with an Avery template. Use the drop down menu to select label type and label size, check the preview, and print barcode labels. Save the settings for the next run.

📌 Q: How do I test if my labels will scan everywhere?

💭 A: Run a quick test with two scanners (handheld and phone). Check contrast, quiet zone, and size. If staff struggle to decode, increase symbol width slightly and reprint a single row before scaling.

📌 Q: Do I need a UPC for every product?

💭 A: If you sell through mainstream retail or marketplaces that require it, yes. For internal inventory, you can use Code128 or your own SKU system. Confirm each channel’s services and optional fields before you commit.eliminates ongoing ink costs. It’s a great printer to pair with your existing setup.

📌 Q: What if my labels keep misprinting or shifting?

💭 A: Clean the head, re-seat the roll, and recalibrate. Confirm format, label size, and match between template and stock. If the job keeps failing, review the source file for extra space or characters that got inserted by mistake.

📌 Q: What are the best ways to choose and use a barcode label maker?

💭 A: There are usually three options for small businesses: compact printers for low volume, mid-range models for growth, and industrial units for warehouses. It’s critical to pick the right one for your needs. Once set up, add a clear sign near the printer with step-by-step instructions. This is especially helpful for new staff learning how to write and print templates correctly. Done right, barcode label makers save time and prevent errors, which means faster service and happier customers.